RF Chip Wirewound Inductors (TRCM)

RF Chip Wirewound inductors Go To Extremes Superior Performance. Miniaturisation of today's electrical and electronic devices requires component manufacturers to increase the performance of components without increasing footprint. DeMint (TRCM) series utilities wirewound technology that offers wide Pad inductor with the highest SRF carrying capability, highest usable frequency range, and the best Q factor of the narrow pad (TREM) and (TREC) series.

The latest wirewound chip inductor (TRCM) series offers improved performance in the same compact molded case size. These series conform to the RoHS directive and Lead-free. Custom parts are available on request. DeMint will also produce devices outside these specifications to meet specific customer requirements, please contact our sales for more information. Download complete specification RF Chip Inductors (TRCM) PDF (386KB)

A Brief Introduction to the Product:

SMD Inductors CM322522 and CM453232 series are revolutionary, high reliable wire wound components for communication, equipment, instruments, video & audio have been developed in response to the trend toward higher density mounting of inductor parts in electric circuits.

Materials:

- Ferrite DR core, enamelled copper wire, tinned copper flat, epoxy novolac moldind compound

- High resistance to heat and humidity.

- Resistant to mechanical shocks and pressures.

- Accurate dimensions for automatically surface mounted.

- Good heat durability that withstands lead-free compatible reflow soldering conditions.

- Other electronic equipment including HDDs and ODDs.

- Audio-visual equipment including TVs,VCRs and digital cameras.

- Electronic equipment used in onboard automobile equipment including car audio and ECU systems.

- Electronic equipment used in communication infrastructures infrastructures including xDSL and mobile base stations.

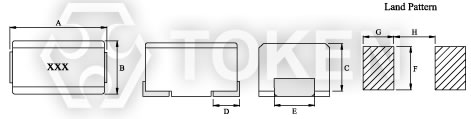

| Configurations & Dimensions (Unti: mm) (TRCM) | |||||||||

|

|||||||||

| Type | A | B | C | D | E | F | G | H | |

| TRCM322522(1210) | 3.2 ± 0.3 | 2.5 ± 0.2 | 2.2 ± 0.2 | 0.4  |

1.9 ± 0.1 | 3.0 | 1.0 | 2.0 | |

| TRCM453232(1812) | 4.5 ± 0.3 | 3.2 ± 0.2 | 3.2 ± 0.2 | 0.4  |

2.6 ± 0.1 | 4.0 | 1.5 | 3.0 | |

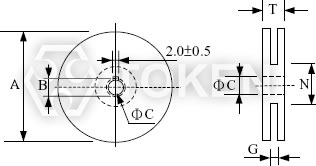

| Reel & Packaging (Unit: mm) (TRCM) | ||||||||

|

||||||||

| TYPE | A | B | C | D | G | N | T | |

| 8mm | 178 | 21.0±0.8 | 13.0±0.5 | 8 | 10 max | 50 min | 14.4 max | |

| 12mm | 178 | 21.0±0.8 | 13.0±0.5 | 10 | 14 max | 50 min | 14.4 max | |

| Standard Electrical Characteristics (TRCM322522) - EIA 1210 | ||||||

| Part No. | Inductance (µH) |

Q (min) |

Test Freq. (MHZ) |

SRF (MHz)(min) |

DCR (Ω)(max) |

IDC (mA) |

| TRCM322522 - 010J | 0.01 ± 5% | 15 | 100 | 2500 | 0.13 | 450 |

| TRCM322522 - 012J | 0.012 ± 5% | 17 | 100 | 2300 | 0.14 | 450 |

| TRCM322522 - 015J | 0.015 ± 5% | 19 | 100 | 2100 | 0.16 | 450 |

| TRCM322522 - 018J | 0.018 ± 5% | 21 | 100 | 1900 | 0.18 | 450 |

| TRCM322522 - 022J | 0.022 ± 5% | 23 | 100 | 1700 | 0.2 | 450 |

| TRCM322522 - 027J | 0.027 ± 5% | 23 | 100 | 1500 | 0.22 | 450 |

| TRCM322522 - 033J | 0.033 ± 5% | 25 | 100 | 1400 | 0.24 | 450 |

| TRCM322522 - 039J | 0.039 ± 5% | 25 | 100 | 1300 | 0.27 | 450 |

| TRCM322522 - 047J | 0.047 ± 5% | 26 | 100 | 1200 | 0.3 | 450 |

| TRCM322522 - 056J | 0.056 ± 5% | 26 | 100 | 1100 | 0.33 | 450 |

| TRCM322522 - 068J | 0.068 ± 5% | 27 | 100 | 1000 | 0.36 | 450 |

| TRCM322522 - 082J | 0.082 ± 5% | 27 | 100 | 900 | 0.4 | 450 |

| TRCM322522 - R10J | 0.1 ± 5% | 28 | 100 | 700 | 0.44 | 450 |

| TRCM322522 - R12J | 0.12 ± 5% | 30 | 25.2 | 500 | 0.22 | 450 |

| TRCM322522 - R15J | 0.15 ± 5% | 30 | 25.2 | 400 | 0.28 | 450 |

| TRCM322522 - R18J | 0.18 ± 5% | 30 | 25.2 | 400 | 0.28 | 450 |

| TRCM322522 - R22J | 0.22 ± 5% | 30 | 25.2 | 350 | 0.32 | 450 |

| TRCM322522 - R27J | 0.27 ± 5% | 30 | 25.2 | 320 | 0.36 | 450 |

| TRCM322522 - R33J | 0.33 ± 5% | 30 | 25.2 | 300 | 0.4 | 250 |

| TRCM322522 - R39J | 0.39 ± 5% | 30 | 25.2 | 250 | 0.45 | 450 |

| TRCM322522 - R47J | 0.47 ± 5% | 30 | 25.2 | 220 | 0.5 | 450 |

| TRCM322522 - R56J | 0.56 ± 5% | 30 | 25.2 | 180 | 0.55 | 450 |

| TRCM322522 - R68J | 0.68 ± 5% | 30 | 25.2 | 160 | 0.6 | 450 |

| TRCM322522 - R82J | 0.82 ± 5% | 30 | 25.2 | 140 | 0.65 | 450 |

| TRCM322522 - 1R0J | 1 ± 5% | 30 | 7.96 | 120 | 0.7 | 400 |

| TRCM322522 - 1R2J | 1.2 ± 5% | 30 | 7.96 | 100 | 0.75 | 390 |

| TRCM322522 - 1R5J | 1.5 ± 5% | 30 | 7.96 | 85 | 0.85 | 370 |

| TRCM322522 - 1R8J | 1.8 ± 5% | 30 | 7.96 | 80 | 0.9 | 350 |

| TRCM322522 - 2R2J | 2.2 ± 5% | 30 | 7.96 | 75 | 1 | 320 |

| TRCM322522 - 2R7J | 2.7 ± 5% | 30 | 7.96 | 70 | 1.1 | 290 |

| TRCM322522 - 3R3J | 3.3 ± 5% | 30 | 7.96 | 60 | 1.2 | 260 |

| TRCM322522 - 3R9J | 3.9 ± 5% | 30 | 7.96 | 55 | 1.3 | 250 |

| TRCM322522 - 4R7J | 4.7 ± 5% | 30 | 7.96 | 50 | 1.5 | 220 |

| TRCM322522 - 5R6J | 5.6 ± 5% | 30 | 7.96 | 45 | 1.6 | 200 |

| TRCM322522 - 6R8J | 6.8 ± 5% | 30 | 7.96 | 40 | 1.8 | 180 |

| TRCM322522 - 8R2J | 8.2 ± 5% | 30 | 7.96 | 35 | 2 | 170 |

| TRCM322522 - 100J | 10 ± 5% | 30 | 2.52 | 30 | 2.1 | 150 |

| TRCM322522 - 120J | 12 ± 5% | 30 | 2.52 | 20 | 2.5 | 140 |

| TRCM322522 - 150J | 15 ± 5% | 30 | 2.52 | 20 | 2.8 | 130 |

| TRCM322522 - 180J | 18 ± 5% | 30 | 2.52 | 20 | 3.3 | 120 |

| TRCM322522 - 220J | 22 ± 5% | 30 | 2.52 | 20 | 3.7 | 110 |

| TRCM322522 - 270J | 27 ± 5% | 30 | 2.52 | 20 | 5 | 80 |

| TRCM322522 - 330J | 33 ± 5% | 30 | 2.52 | 17 | 5.6 | 70 |

| TRCM322522 - 390J | 39 ± 5% | 30 | 2.52 | 16 | 6.4 | 65 |

| TRCM322522 - 470J | 47 ± 5% | 30 | 2.52 | 15 | 7 | 60 |

| TRCM322522 - 560J | 56 ± 5% | 30 | 2.52 | 13 | 8 | 55 |

| TRCM322522 - 680J | 68 ± 5% | 30 | 2.52 | 12 | 9 | 50 |

| TRCM322522 - 820J | 82 ± 5% | 30 | 2.52 | 11 | 10 | 45 |

| TRCM322522 - 101J | 100 ± 5% | 20 | 0.796 | 10 | 10 | 40 |

| TRCM322522 - 121J | 120 ± 5% | 20 | 0.796 | 10 | 11 | 70 |

| TRCM322522 - 151J | 150 ± 5% | 20 | 0.796 | 8 | 15 | 65 |

| TRCM322522 - 181J | 180 ± 5% | 20 | 0.796 | 7 | 17 | 60 |

| TRCM322522 - 221J | 220± 5% | 20 | 0.796 | 7 | 21 | 50 |

| TRCM322522 - 271J | 270 ± 5% | 20 | 0.796 | 6 | 28 | 45 |

| TRCM322522 - 331J | 330 ± 5% | 20 | 0.796 | 5 | 34 | 40 |

| TRCM322522 - 391J | 390 ± 5% | 20 | 0.796 | 5 | 36 | 35 |

| TRCM322522 - 471J | 470 ± 5% | 20 | 0.796 | 4 | 40 | 25 |

| Standard Electrical Characteristics (TRCM453232) - EIA 1812 | ||||||

| Part No. | Inductance (µH) |

Q (min) |

Test Freq. (MHZ) |

SRF (MHz)(min) |

DCR (Ω)(max) |

IDC (mA) |

| TRCM453232 - 1R0J | 1 ± 5% | 50 | 7.96 | 100 | 0.5 | 450 |

| TRCM453232 - 1R2J | 1.2 ± 5% | 50 | 7.96 | 80 | 0.55 | 430 |

| TRCM453232 - 1R5J | 1.5 ± 5% | 50 | 7.96 | 70 | 0.6 | 410 |

| TRCM453232 - 1R8J | 1.8 ± 5% | 50 | 7.96 | 60 | 0.65 | 390 |

| TRCM453232 - 2R2J | 2.2 ± 5% | 50 | 7.96 | 55 | 0.7 | 380 |

| TRCM453232 - 2R7J | 2.7 ± 5% | 50 | 7.96 | 50 | 0.75 | 370 |

| TRCM453232 - 3R3J | 3.3 ± 5% | 50 | 7.96 | 45 | 0.8 | 355 |

| TRCM453232 - 3R9J | 3.9 ± 5% | 50 | 7.96 | 40 | 0.9 | 330 |

| TRCM453232 - 4R7J | 4.7 ± 5% | 50 | 7.96 | 35 | 1 | 315 |

| TRCM453232 - 5R6J | 5.6 ± 5% | 50 | 7.96 | 33 | 1.1 | 300 |

| TRCM453232 - 6R8J | 6.8 ± 5% | 50 | 7.96 | 27 | 1.2 | 285 |

| TRCM453232 - 8R2J | 8.2 ± 5% | 50 | 7.96 | 25 | 1.4 | 270 |

| TRCM453232 - 100J | 10 ± 5% | 50 | 2.52 | 20 | 1.6 | 250 |

| TRCM453232 - 120J | 12 ± 5% | 50 | 2.52 | 18 | 2 | 225 |

| TRCM453232 - 150J | 15 ± 5% | 50 | 2.52 | 17 | 2.5 | 200 |

| TRCM453232 - 180J | 18 ± 5% | 50 | 2.52 | 15 | 2.8 | 190 |

| TRCM453232 - 220J | 22 ± 5% | 50 | 2.52 | 13 | 3.2 | 180 |

| TRCM453232 - 270J | 27 ± 5% | 50 | 2.52 | 12 | 3.6 | 170 |

| TRCM453232 - 330J | 33 ± 5% | 50 | 2.52 | 11 | 4 | 160 |

| TRCM453232 - 390J | 39 ± 5% | 50 | 2.52 | 10 | 4.5 | 150 |

| TRCM453232 - 470J | 47 ± 5% | 50 | 2.52 | 10 | 5 | 140 |

| TRCM453232 - 560J | 56 ± 5% | 50 | 2.52 | 9 | 5.5 | 135 |

| TRCM453232 - 680J | 68 ± 5% | 50 | 2.52 | 9 | 6 | 130 |

| TRCM453232 - 820J | 82 ± 5% | 50 | 2.52 | 8 | 7 | 120 |

| TRCM453232 - 101J | 100 ± 5% | 40 | 0.796 | 8 | 8 | 110 |

| TRCM453232 - 121J | 120 ± 5% | 40 | 0.796 | 6 | 8 | 110 |

| TRCM453232 - 151J | 150 ± 5% | 40 | 0.796 | 5 | 9 | 105 |

| TRCM453232 - 181J | 180 ± 5% | 40 | 0.796 | 5 | 9.5 | 102 |

| TRCM453232 - 221J | 220 ± 5% | 40 | 0.796 | 4 | 10 | 100 |

| TRCM453232 - 271J | 270 ± 5% | 40 | 0.796 | 4 | 12 | 92 |

| TRCM453232 - 331J | 330 ± 5% | 40 | 0.796 | 3.5 | 14 | 85 |

| TRCM453232 - 391J | 390 ± 5% | 40 | 0.796 | 3 | 16 | 80 |

| TRCM453232 - 471J | 470 ± 5% | 40 | 0.796 | 3 | 26 | 62 |

| TRCM453232 - 561J | 560 ± 5% | 30 | 0.796 | 3 | 30 | 50 |

| TRCM453232 - 681J | 680 ± 5% | 30 | 0.796 | 3 | 30 | 50 |

| TRCM453232 - 821J | 820 ± 5% | 30 | 0.796 | 2.5 | 35 | 30 |

| TRCM453232 - 102J | 1000 ± 5% | 30 | 0.252 | 2.5 | 40 | 30 |

| Mechanical Performance Test (TRCM322522, TRCM453232) | ||

| REQUIREMENTS | CHARACTERISTICS | TEST METHOD(DIS C 5321) |

| Terminal Strength | No evidence of damage | Terminals shall withstand a pull of 0.5Kgf in a horizontal direction |

| Vibration | Δ L/L shall be within ±3%. No evidence of damage |

2 hours in each direction of X,Y,Z on p-Board at a frequency range of 10-55-10HZ with 1.5mm amplitude |

| Dropping | Δ L/L shall be within ±3%. No evidence of damage |

Dropping 1m over the ground of concrete or cement |

| Electrical Performance Test (TRCM322522, TRCM453232) | ||

| REQUIREMENTS | CHARACTERISTICS | TEST METHOD(JIS C 5321) |

| Resistance to Soldering Heat |

No evidence of damage Δ L/L shall be within ±3% |

Immerse in the solder (H63A)of 260±5°C for 10±1sec, leave for 2hrs at normal TEMP |

| Solderability | More than 90% surface to be covered with new soldering |

AV100V 60 SEC. |

| Dielectric with withstanding voltage |

No evidence of breakdown resistor 1000 Mohm and over |

DC500V 30 SEC. |

| Insulation Resistance | No veidence of breakdown, resistor 1000 Mohm and over |

DC 500V 30 SEC. |

| Climatic Test (TRCM322522, TRCM453232) | ||

| REQUIREMENTS | CHARACTERISTICS | TEST METHOD(JIS C 5321) |

| LOW TEMP. Characteristics |

No evidence of damage, Δ L/L within ±5%, Q/Q within ±30% |

Immerse in the solder (H63A)of 260±5°C for 10±1sec, leave for 2hrs at normal TEMP. |

| TEMP. Cycling | No evidence of damage, Δ L/L within ±5% |

Keep for 30 min. at TEMP.of -25°C~+85°C at 5 cycle case of TEMP. change from low to high and V.V. |

| Temperature Characteristics |

Δ L/L within ±3% | Δ L/L to be measured at the temperature of between -25°C and +85°C |

| Moiisture load Characteristics |

No evidence of damage, Δ L/L within ±5%, Q/Q within ±30 |

TEMP.40±2°C,Humidity 90~95% 96± 2hrs, measurements shall be performed after 1~2hrs at normal TEMP.. |

| High TEMP. overload Characteristics |

No evidence of damage, Δ L/L within ±5%, Q/Q within ±30 |

Leave for 96±2hrs in a bath of TEMP.85±2°C, measurements shall be performed after 1~2hrs at normal TEMP. |

| Order Codes (TRCM322522, TRCM453232) | ||||||||||||||||||||||

| TRCM322522 | - | R10 | J | |||||||||||||||||||

|  |  | ||||||||||||||||||||

|

|

|

||||||||||||||||||||