Current Sensing Power Shunts (LRS)

The advanced alloy shunt technology of TOKEN (LRS) spells out the high-power current sensing resistor.

Design of Bare Open Surface Mounting Chip Alloy allows air flow to achieve maximum cooling effect, so that PCB retains less heat. Welding flame protection structure feature provides 20ppm TCR temperature coefficient, low inductance. These characteristics make LRS an excellent choice for all high-power power supply and power applications that are not impacted by most environmental stresses.

For the development of high current applications for automated control and sensing power supplies, the DeMint current sensing chip shunt (LRS) uses Manganese Copper (Manganin), Kama Alloy (KAMAR NiCr20AlSi), and Ferro Chrome Aluminum Alloy (FeCrAl) which featuring antioxidant and high temperature resistant thermal corrosion properties as alloy welding structure. Standard surface mounting spacing design is suitable for reflow welding and automatic mounting machine applications.

Designed specifically for high current applications LRS, the power can reach 3W, 5W, 6W, and 7W. The range of ultra-low resistance is from 0.1mΩ to 6mΩ. There are many options in selecting precision tolerances (±1%, ±2%, ±5%). Two types of chip dimensions are available: standard size 2512, 3920, and 5930; special size 3921, 4026, 4527, and 5931. DeMint realizes small size, high power design, lower cost and higher performance current sensing shunts.

LRS provides embossed tape packaging, size 2512 1Kpcs per reel, 3920 2.5Kpcs per reel, 5930 2Kpcs per reel, products meet RoHS standards and lead-free requirements. Customers can specify resistance, size and specifications to meet the design challenges and specific technical requirements. Please contact DeMint Business Department for the latest product information.

Download PDF Specification : Current Sensing Power Shunts (LRS).

- Resistance down to 0.1mΩ to 6mΩ.

- TCR down to ±20ppm/°C and ±50ppm/°C.

- Sustain high temperature, lead-free and RoHS compliant.

- Welded construction, air cooling, Strong stability of circuit.

- Tolerance ±1%, ±2%, and ±5%. Rated Power 3W, 5W, 6W, and 7W.

- Frequency converters.

- Automatic control power supply.

- Power modules. Communication system.

- Current sensor for power hybrid applications.

- High current applications for the automotive market.

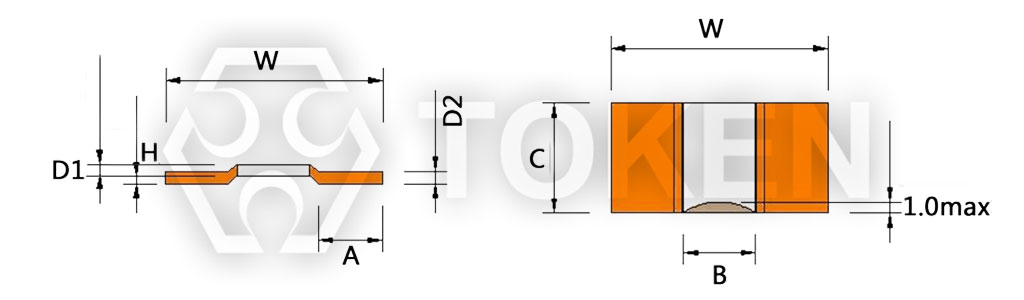

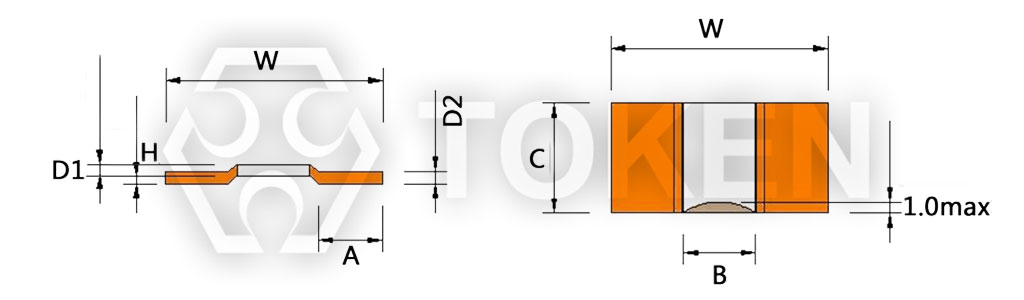

| LRS - M/K Standard Size (Unit:mm) | |||||||||||

Alloy Shunt Resistors (LRS) - M/K Series Dimensions |

|||||||||||

| Type | Power (W) |

Material | Size | B (mm) |

W (mm) |

A (mm) |

C (mm) |

H (mm) |

D1 (mm) |

D2 (mm) |

Resistance Value (mΩ) |

| LRS | 3 | M | 2512 | 3.0±0.3 | 6.3±0.2 | 1.2±0.2 | 3.1±0.3 | 0.5±0.1 | 1.5 | 1.5 | 0.3 |

| 0.88 | 0.88 | 0.5 | |||||||||

| 0.5 | 0.5 | 1 | |||||||||

| K | 1.31 | 1.31 | 1 | ||||||||

| 0.65 | 0.65 | 2 | |||||||||

| 0.43 | 0.43 | 3 | |||||||||

| 5 | M | 3920 | 4.5±0.3 | 10±0.2 | 2.2±0.2 | 5.1±0.4 | 0.5±0.1 | 1.5 | 1.5 | 0.2 | |

| 1.37 | 1.37 | 0.3 | |||||||||

| 0.83 | 0.83 | 0.5 | |||||||||

| 0.4 | 0.4 | 1 | |||||||||

| K | 1.16 | 1.16 | 1 | ||||||||

| 0.37 | 0.37 | 3 | |||||||||

| 0.28 | 0.28 | 5 | |||||||||

| 7 | M | 5930 | 5.0±0.3 | 15±0.3 | 4.2±0.3 | 7.6±0.4 | 0.5±0.1 | 1.5 | 1.5 | 0.2 | |

| 0.75 | 0.75 | 0.4 | |||||||||

| 0.6 | 0.6 | 0.5 | |||||||||

| 0.41 | 0.41 | 0.75 | |||||||||

| K | 0.86 | 0.86 | 1 | ||||||||

| 0.4 | 0.4 | 2 | |||||||||

| 0.29 | 0.29 | 3 | |||||||||

| LRS - M/K Special Size (Unit:mm) | |||||||||||

| Type | Power (W) |

Material | Size | B (mm) |

W (mm) |

A (mm) |

C (mm) |

H (mm) |

Resistance Value (mΩ) |

||

| LRS | 5 | M | 3921 | 4.5±0.3 | 10±0.2 | 2.2±0.2 | 5.2±0.3 | 0.5±0.1 | 0.2 ~ 5 | ||

| 5 | K | 3921 | 4.5±0.3 | 10±0.2 | 2.2±0.2 | 5.2±0.3 | 0.5±0.1 | 0.2 ~ 5 | |||

| 6 | M | 4026 | 4.5±0.3 | 10±0.2 | 2.2±0.2 | 6.6±0.4 | 0.5±0.1 | 0.2 ~ 3 | |||

| 6 | K | 4026 | 4.5±0.3 | 10±0.2 | 2.2±0.2 | 6.6±0.4 | 0.5±0.1 | 0.2 ~ 3 | |||

| 6 | M | 4527 | 4.5±0.3 | 11.5±0.2 | 3.0±0.3 | 6.9±0.4 | 0.5±0.1 | 0.4 ~ 3 | |||

| 6 | K | 4527 | 4.5±0.3 | 11.5±0.2 | 3.0±0.3 | 6.9±0.4 | 0.5±0.1 | 0.4 ~ 3 | |||

| 7 | M | 5931 | 5.0±0.3 | 15±0.3 | 4.2±0.3 | 7.8±0.4 | 0.5±0.1 | 0.1 ~ 0.75 | |||

| 7 | K | 5931 | 5.0±0.3 | 15±0.3 | 4.2±0.3 | 7.8±0.4 | 0.5±0.1 | 1 ~ 3 | |||

| LRS - F Dimensions (Unit:mm) | |||||||||||

Current Sensing Power Shunts (LRS) - F Series Dimensions |

|||||||||||

| Type | Power (W) |

Material | Size | B (mm) |

W (mm) |

A (mm) |

C (mm) |

H (mm) |

D1 (mm) |

D2 (mm) |

Resistance Value (mΩ) |

| LRS | 3 | F | 2512 | 3.0±0.3 | 6.3±0.2 | 1.2±0.2 | 3.1±0.3 | 0.5±0.1 | 1.4 | 1.4 | 1 |

| 3.0±0.3 | 6.3±0.2 | 1.2±0.2 | 3.1±0.3 | 0.5±0.1 | 0.7 | 0.7 | 2 | ||||

| 3.0±0.3 | 6.3±0.2 | 1.2±0.2 | 3.1±0.3 | 0.5±0.1 | 3 | 0.47 | 0.47 | ||||

| 3.0±0.3 | 6.3±0.2 | 1.2±0.2 | 3.1±0.3 | 0.5±0.1 | 0.35 | 0.35 | 4 | ||||

| 3.0±0.3 | 6.3±0.2 | 1.2±0.2 | 3.1±0.3 | 0.5±0.1 | 0.28 | 0.28 | 5 | ||||

| 3.0±0.3 | 6.3±0.2 | 1.2±0.2 | 3.1±0.3 | 0.5±0.1 | 0.24 | 0.24 | 6 | ||||

| 5 | F | 3920 | 4.5±0.3 | 10.0±0.2 | 2.2±0.2 | 5.1±0.4 | 0.5±0.1 | 1.28 | 1.28 | 1 | |

| 4.5±0.3 | 10.0±0.2 | 2.2±0.2 | 5.1±0.4 | 0.5±0.1 | 0.64 | 0.64 | 2 | ||||

| 4.5±0.3 | 10.0±0.2 | 2.2±0.2 | 5.1±0.4 | 0.5±0.1 | 0.43 | 0.43 | 3 | ||||

| 4.5±0.3 | 10.0±0.2 | 2.2±0.2 | 5.1±0.4 | 0.5±0.1 | 0.32 | 0.32 | 4 | ||||

| 4.5±0.3 | 10.0±0.2 | 2.2±0.2 | 5.1±0.4 | 0.5±0.1 | 0.26 | 0.26 | 5 | ||||

| 7 | F | 5930 | 5.0±0.3 | 15±0.3 | 4.2±0.3 | 7.6±0.4 | 0.5±0.1 | 0.96 | 0.96 | 1 | |

| 5.0±0.3 | 15±0.3 | 4.2±0.3 | 7.6±0.4 | 0.5±0.1 | 0.48 | 0.48 | 2 | ||||

| 5.0±0.3 | 15±0.3 | 4.2±0.3 | 7.6±0.4 | 0.5±0.1 | 0.32 | 0.32 | 3 | ||||

| 5.0±0.3 | 15±0.3 | 4.2±0.3 | 7.6±0.4 | 0.5±0.1 | 0.24 | 0.24 | 4 | ||||

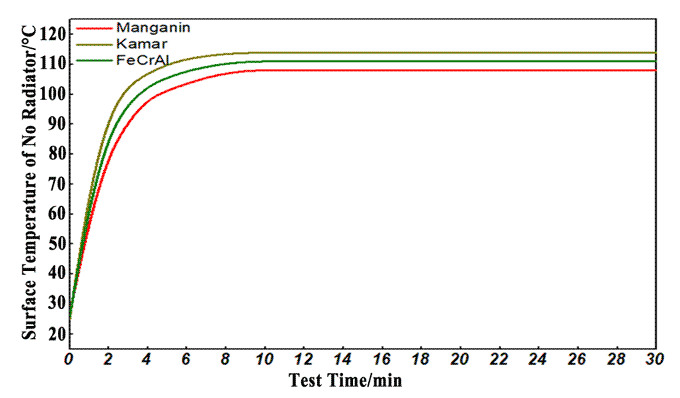

| Surface Temperature Curve LRS - Technical Specifications |

Surface Temperature Curve (LRS) |

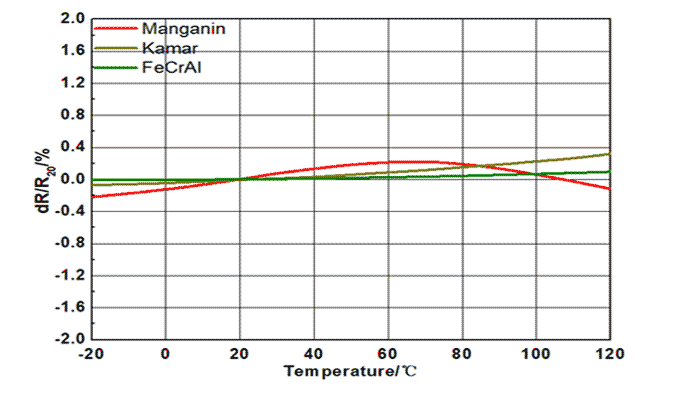

| TCR Derating Curve LRS - Technical Specifications |

TCR Derating Curve (LRS) |

| LRS - Environmental Characteristics | ||

| Iterms | Requirement | Test Methods |

| Temperature Cycling | ±0.5% | JESD22 1000 Cycles (-55°C to +125°C). Measurement at 24±2 hours after test conclusion. |

| High Temperature Exposure | ±0.5% | MIL-STD-202 1000hrs. @T=125°C. Unpowered.Measurement at 24±2 hours after test conclusion. |

| Moisture Resistance | ±0.5% | MIL-STD-202 t=24 hrs/cycle. Measurement at 24±2 hours after test conclusion. Note: Steps 7a & 7b not required. Unpowered. |

| Biased Humidity | ±0.5% | MIL-STD-202 1000hrs 85°C/85% RH. Measurement at 24±2 hours after test conclusion. Note: Specified conditions: 10% of operating power. |

| Operational Life | ±0.5% | MIL-STD-202 Condition D Steady State TA=125°C at rated power. Measurement at 24±2 hours after test conclusion. |

| Solderability | 95% Coverage Minimum. | J-STD-002C 245°C±5°C, 5s+0.5s/-0. |

| Resistance to Soldering Heat | ±0.5% | MIL-STD-202 260°C±5°C, 10s±1s. Measurement at 24±2 hours after test conclusion. |

| Short Time Overload | ±0.5% | MIL-STD-202 5 × Rated power for 5s. Measurement at 24±2 hours after test conclusion. |

| Thermal Shock | ±1% | MIL-STD-202 -55°C/+125°C, 300 Cycles. Maximumtransfer time 20s, Dwell time 15min. |

| Vibration | ±0.5% | MIL-STD-202 5g's for 20 min, 12 cycles each of 3 orientations. Note: Use 8"X5" PCB .031" thick 7" secure points on one long side and secure points at corners of opposite sides which parts mounted with in 2 from any secure point. Test from 10-2000 Hz. Measurement at 24±2 hours after test conclusion. |

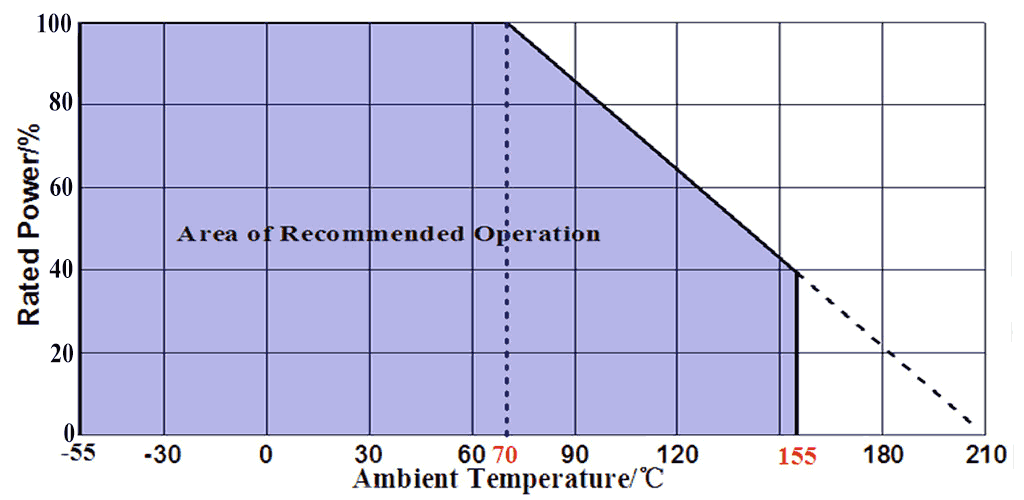

| Power Derating Curve (LRS) |

Rated power VS Ambient temperature (Power Derating Cruve) |

| LRS - 包裝規格 | |||||||||||

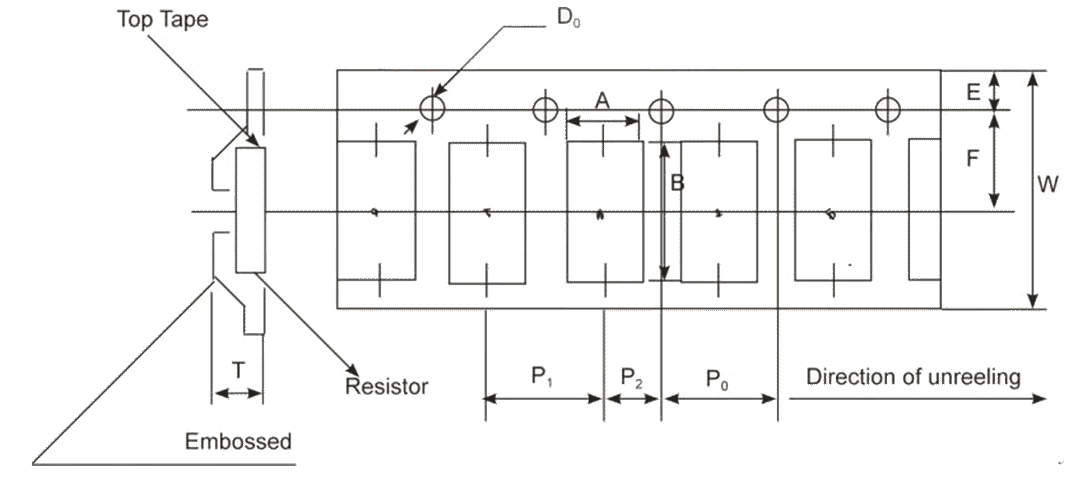

LRS - Embossed Plastic Tape Specifications |

|||||||||||

| Size | A (mm) | B (mm) | W (mm) | E (mm) | F (mm) | P0 (mm) | P1 (mm) | P2 (mm) | D0 (mm) | T (mm) | Quantity (EA)/ Pieces |

| 2512 | 4.3 | 7.6 | 16 | 1.55 | 7.5 | 3.85 | 7.7 | 7.7 | 1.5 | 1.7 | 1000 |

| 3920 | 6.0 | 11 | 24 | 1.55 | 11.2 | 6 | 12 | 12 | 1.5 | 2.0 | 2500 |

| 5930 | 8.6 | 16 | 24 | 1.55 | 10.8 | 6 | 12 | 12 | 1.5 | 2.4 | 2000 |

| Large Current Sensing Chip Resistor Shunts LRS - Order Code | ||||||||||||||||||||||||||||||||||||||||||

| LRS | 3 | M | 0m30 | J | ||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||||||||||||||