Wide Terminal Current-Sensing Chips (CSM)

Using a wider side as the connection in the mounting plate, the wide terminal current sense chip reinforces the solder joint and is reliably held to achieve higher power ratings. The wide-terminal current sensor saves space and reduces the amount of resistors in high-density board designs due to its ideal structure to suppress heat generation.

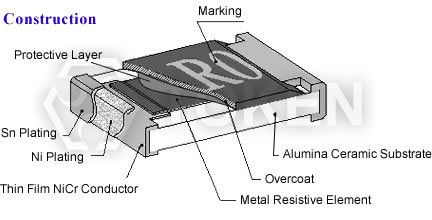

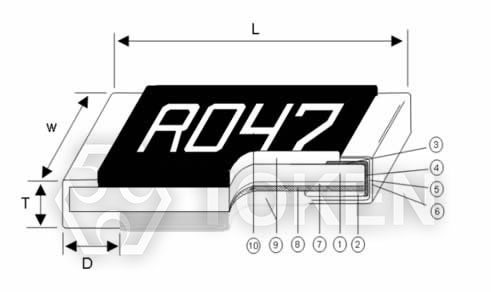

Thick Film Current-Sensing Chips (CS)

Based on thick film technology, the parasitic inductance of these chips is much lower than that of wire wound and leaded components. Token's thick film Token CS low ohmic current sense chip resistors are low cost, capable of providing low TCR down to ±100ppm/°C, resistance values as low as 1mΩ, and power consumption up to 3 watts.

Thick Film Current-Sensing Chips (CS Series)

Metal Foil Current-Sensing Chips (CSM)

Metal foil current sense resistors made of manganese-copper alloy were developed with the substrate to provide better heat dissipation and a wider resistance range of up to 700mΩ. Metal foil The CSM series has a lower EMF under temperature variations. μ0.03μV/°C is more likely to withstand harsh conditions. In the metal foil type, the TCR ranges from 50 to 100 ppm, the power is up to 5W, and the resistance is as low as 1mΩ.

Metal Foil Current-Sensing Chips (CSM)

Four-Terminal Current-Sensing Chips (LRF)

For accurate measurement of circuit design, lower power consumption, higher accuracy and smaller space requirements are important features of electronic control units. In order to minimize power consumption, it is necessary to measure the large current across the (Rsense) resistor, and the high-side current sense amplifier IC must accurately monitor the current.

A four-terminal current-sense resistor that separates the current transfer from the voltage-sensing terminal, from the ideal Kelvin configuration, improves voltage and current measurement accuracy. They also improve interference and thermoelectric effects in higher power applications.

Four-Terminal Current-Sensing Chips (LRF)

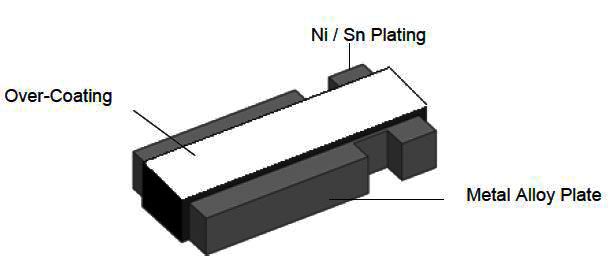

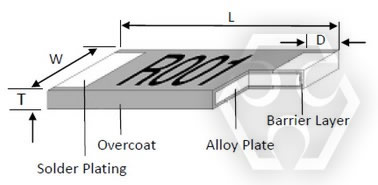

Metal Plate Current-Sensing Chips

(LRC, LRP, LRM, LRE, LREA)

A simple structure without multiple cuts, metal plate current sense resistors provide low TCR down to ±50ppm/°C, Up to 5W rated power, high frequency performance and low resistance down to 0.1mΩ.

Metal Plate Current-Sensing Chips (LRC, LRP, LRM, LRE, LREA)

Catalogue Download

Download Design & Selection in PDF file.

How to Design & Select Current Sense Devices

Generally, a resistor manufacturer will offer their most popular devices as standards creating a reference for Engineers to design from. Typically, and especially true in the Current Sensing category, a standard device is available for most common applications. However, for applications requiring parameters that are not currently considered industry standards, DeMint is uniquely equipped to offer design and development services at comparatively lower costs than our competitors. In this case, the following information is required to effectively design a current sensing resistor:

Point 1 - Power Rating:

Calculate the power dissipation under operating conditions

Equation: Pavg = IRMS2 × R; where Power (P), Current (I), Root Mean Square (RMS), Resistance (R)

.

Allowing for transient or fault conditions and high ambient temperature if applicable, select the required power rating.

For many current sense resistors, only the maximum temperature of the solder joints limits the power rating.

Power rating is thus a function of the PCB layout design as well as of component selection (see point 4.).

Point 2 - Resistance Value:

Determine the minimum suitable resistance value. This is the lowest value of peak sense voltage consistent with an acceptable signal to noise ratio, divided by the peak current to be measured.

Point 3 - Temperature Coefficient of Resistance (TCR):

Establish the accuracy needed in terms of a tolerance on the value and of sensitivity to temperature. The latter factor is quoted as Temperature Coefficient of Resistance (TCR), defined as the value change in parts per million for a 1°C temperature rise. It is generally higher for low value resistors because the metallic leads or terminations, which have a very high TCR, make up a significant part of the total resistance value.

To achieve acceptable accuracy it is normally necessary to make four-terminal (Kelvin) connections to the resistor. This means connecting the current carrying tracks and the voltage sense tracks directly to the component pads. Even when this is done, there is still some pad area and solder in series with the resistor, which may compromise the actual tolerance and TCR of the soldered part. For very high accuracy or very low values, a four-terminal resistor type is the best choice.

Point 4 - PCB Layout:

Care must be taken when laying out a PCB if the stated performance of a sense resistor is to be achieved. The current carrying tracks should be as wide as possible, using multiple layers connected by many vias near the component pad. This also improves the heatsinking of the joints.

The best way to make four-terminal connections to a two-terminal through-hole resistor is to use different sides of the PCB for the current and voltage connections. Failing this, current and voltage tracks should connect to opposite sides of the component pad.

In order to avoid interference from stray magnetic fields, the loop area contained by the sense resistor, the voltage sense tracks and the sense circuit input should be minimised. This means keeping the sense circuitry as close as possible to the sense resistor and running the voltage sense tracks close to each other.

Point 5 - High Frequency Applications:

Where transient or AC currents involving high frequencies are to be sensed, the self-inductance of the resistor must be minimised. Wirewound or spiralled film parts should be avoided, in favour of bulk metal or low value chips.

Point 6 - High Heat Dissipation:

When using a metallic element shunt with high heat dissipation and low sense voltage, consideration may need to be given to thermoelectric voltages. The junction between a metallic resistance element and metal terminations acts as a thermocouple, generating a voltage proportional to the temperature difference across it.

A leaded metallic element sense resistor is therefore like two thermocouples back to back. This means that, if the temperature differences across both junctions are equal, the error voltage is cancelled out. This is achieved by making the design thermally symmetrical, namely, by presenting both terminals with similar heatsinking and by keeping any other heat sources thermally distant.

Terminology & Glossary

What is a "Current Sense"?

Current sensing products are the newest and fastest growing resistive products in the industry today. As with most passive products, the majority of new designs are surface mount. These resistors are used to monitor the current in a circuit and translate the amount of current in that circuit into a voltage that can be easily measured and monitored.

Current Detecting Resistors

Due to the increase in sales of notebook PCs, the demand for the DC/DC converter has shown rapid growth because of its high-energy conversion efficiency, and its precise current-limiting capability. However, to ensure the performance of the multiple output DC/DC converter, the current limiting voltage must be detected precisely to protect an expensive notebook PC from an overload, which is generally due to shorts within the capacitors used in these devices.

For high-energy conversion efficiency various control ICs have been developed that utilize resistive components. To achieve the perfect cutoff mode of the DC load current at the programmed current-limiting voltage of the control IC, a very stable and accurate sense resistor with the following characteristics is required for precise voltage comparison.

- Very Low Ohmic Value should be below 25mΩ for minimizing power consumption at the current sensing resistor.

- Tight Tolerance must be ±1% or tighter for maximizing the current supply within the limit of acceptable current.

- Low TCR is required for current sensing across the ambient temperature range of 0°C to 60°C.

- Low Thermal EMF for an accurate comparison between the programmed current-limiting voltage of the control IC and the detected voltage.

Furthermore, the self-inductance should be for high frequency applications. Recommended types are general purpose current sensing products or a flame retardant type.

How 4-Terminal Resistor Works:

How 4-Terminal Sense Resistor Works

How 4-Terminal Sense Resistor WorksHigh precision resistors used for current sensing are usually low ohmic value devices suitable for four terminal connection. To use a four terminal resistor, we force a current from Terminal 1 to Terminal 2. It's current, so the unknown resistances attached to Terminal 1 and Terminal 2 don't affect the amount of the current. The same number of electrons per second flow through from T1 to T2, regardless of the resistance.

A voltmeter measures the resulting voltage drop across the ultra-precise resistor, measuring through the unknown resistors attached to Terminal 3 and Terminal 4. The voltmeter's input impedance is very, very high compared to the unknown resistors, so the unknown resistors have essentially zero effect (typically less than 0.1 parts-per-million).

So the current flows through the 0.100 ohm resistor, unaffected by the unknown resistors, and we measure the voltage across the 0.100 ohm resistor, unaffected by the unknown resistors. And that's how a 4-terminal resistor works!

Flip Chip Resistors

An unencapsulated resistor chip on which bead-type leads terminate on one face to permit "flip" (face down) mounting of the resistor chip by contact of the leads with interconnective circuitry.

Hot-Spot Temperature

The maximum temperature measured on the resistor due to both internal heating and the ambient operating temperature.

Low Profile

Components designed with "lower than standard heights", to save space and allow clearance when mounted on PCBs.

Maximum Working Voltage

The maximum specified voltage that may be applied across a resistor.

PPM

Parts per million. The terminology used when describing the temperature coefficient.

Screen

The process of printing a network pattern of thick-film ink or paste onto a substrate by means of a squeegee applied to a photo-etched wire-mesh "silk screen" or metal mask.

Current Shunt Resistors

Current shunt resistors are precision low resistance resistors used to measure AC or DC electrical currents by the voltage drop those currents create across the resistance. Sometimes called an ammeter shunt, it is a type of current sensor.

SMT/SMD

Surface-mount technology/surface-mount device.

Zero Ohm Resistors

Products that look like resistors, but actually have no resistance (very very low resistance) and instead perform as jumpers.

General Information of Current Sensing Resistors

Your Current Options - DeMint Electronics′ Current Sense:

As the world becomes more and more technology-driven, the uses for current sensing components will continue to increase. The need for even lower resistance value ranges is already becoming evident, as is the need for these resistors to handle more power. The industry-wide trend is the emergence of smaller and smaller products.

DeMint Electronics offers a wide variety of current sensing products from the industry to military standards, such as current sense in Thin-Film / Thick-Film Technology, Bare Element Resistors, and Open Air Shunts. This enables DeMint to present an astounding number of possible solutions for any circuit design needs.

Applications of Current Detecting Resistors:

DeMint's TCS and CS Series unique form factor provides automotive designers with several advantages.

Both TCS and CS Series are ideal for applications involving window lift motors, fuel pump systems, seat belt pretensioners, and pulsewidth modulator feedback.

The wider resistive element and lower resistance enables higher current to pass through the device.

DeMint's LRC ultra low ohmic metal strip chip series provides the inherent ability to flex slightly and offers stress relief during extreme temperature cycling on typical or metal substrates.

This LRC series is suitable for switch power supply applications (DC-DC Converter, Charger, Adaptor) and power management of monitor.

The open air design of bare element resistor LRA and LRB Series provide a far cooler operation by allowing more air flow

under the resistive element to keep excess heat from being transmitted to the PC board.

They are suitable for high power AC/DC detection of power supply circuit.

DeMint axial moulded BWL series provides power rating up to 10 watts and lower resistance 0.005Ω,

is ideal for all types of current sensing applications including switching and linear power supplies, instruments and power amplifiers.

PDF Current Sensing Resistor Design Notes and Catalogue Download:

DeMint standard current sensing components can be replacement for Vishay, IRC, Ohmite, KOA, Yageo devices with fast delivery and more competitive price. Contact us with your specific needs.