Vitreous Enameled Power Wirewound Resistors - DRB20

Power Wirewound Enameled Resistor (DRB20) Is a cylindrical ceramic tube at both ends clips to fixed terminals. Ceramic tube winding copper nickel or nickel-chromium alloy resistance wire. Surface coated with moisture-resistant, heat-resistant, non-corrosive, non-flammable coatings (such as silicone, epoxy, cement, glazed porcelain, etc.). After high temperature treatment, the resistor dried and insulation fixed, then fitted with fixed foot frame.

Due to good flexibility, (DRB20) can be made of multi-terminal, low inductive resistance, semi-adjustable type of various types of resistors. Resistance range from 1.7Ω to 75KΩ, with power ranges from 8W to 500W, and optional tolerance accuracy of ±1%、±5%、±10%. Size of cylindrical ceramic tube matches with industry standards .

Tubular series power-glaze wire wound resistor (DRB20) widely used as brake resistors, bleeder resistors, aging resistors, brake resistors. According to different occasions, but also can be called brake resistors, discharge resistors, load resistors, current limiting resistors, charging resistors or discharge resistors. Non-inductance series adopts Ayrton Perry winding method to eliminate inductance parasitic effect, so as to minimize inductance, suitable for high energy consumption, high-temperature environment.

Be glazed coating protection, not afraid of external mechanical strength and dust environment. Not only large power and strong, shock-resistant, but also features good heat dissipation. This (DRB20) is easy to install and use. This is suitable for a variety of applications. More than 1.2 times the same specifications or requirements of peer production, more power, can be long time loading and impact. Applications include industrial machinery, load testing, power distribution, instrumentation and automation control devices.

DeMint Electronics (DRB20) vitreous enameled power wirewound resistors meet RoHS compliant, lead-free standard and short production cycle. Those Products widely used in power tools, switch applications, power supplies, welding machines, high voltage applications, consumer product applications, home entertainment, home appliances products. For the customized special applications, please contact our sales to discuss the details.

Download complete datasheet: Vitreous Enameled Power Wirewound Resistors (DRB20)。

Link to more tube-mounted power wirewound resistor series: Smooth Wirewound Tubular Power Resistor (DR) and

Smooth Wound Power Adjustable Resistors (DRS)

- Small size, high power.

- Glaze coating, simple structure, easy to install.

- Fixed resistance and adjustable resistance optional.

- Electric tools, Consumer product applications.

- Power supply, high voltage applications.

- Welding machine, switch applications.

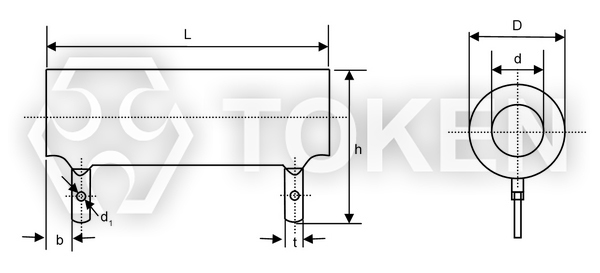

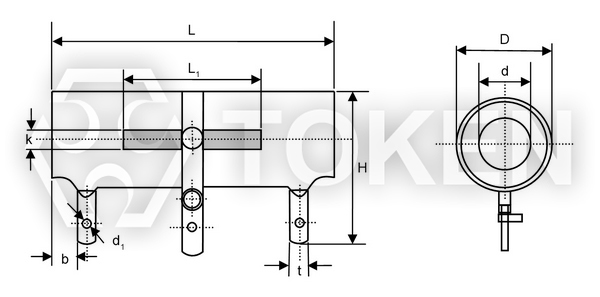

| Power Wirewound Glaze Resistors (DRB20) Dimensions (Unit: mm) | ||||||||||

Power Wirewound Glaze Resistors (DRB20) Dimensions (Unit: mm) Power Wirewound Glaze Adjustable Resistors (DRB20-T) Dimensions (Unit: mm) |

||||||||||

| Type | Dimensions (mm) | |||||||||

| L | D | d | H | h | L1 | K | b | t | d1 | |

| DRB20(T*)-8 | 35±1.5 | 14±2 | 5.5±0.5 | 28.5±2.5 | 3.5±0.8 | 4.5±1 | 2±0.8 | |||

| DRB20(T)-10 | 41±1.5 | 14±2 | 5.5±0.5 | 31±3 | 28.5±2.5 | 20±2 | 6±2 | 3.5±0.8 | 4.5±1 | 2±0.8 |

| DRB20(T)-16 | 45±1.5 | 17±2 | 8±0.5 | 34±3 | 31±2.5 | 23±2 | 6±2 | 3.5±0.8 | 4.5±1 | 2±0.8 |

| DRB20(T)-20 | 51±2 | 17±2 | 8±0.5 | 34±3 | 31±2.5 | 30±3 | 6±2 | 3.5±0.8 | 4.5±1 | 2±0.8 |

| DRB20(T)-25 | 51±2 | 21±2.5 | 12±0.6 | 39±3 | 35±2.5 | 30±3 | 6±2 | 3.5±0.8 | 4.5±1 | 2±0.8 |

| DRB20(T)-30 | 71±2.2 | 21±2.5 | 12±0.6 | 39±3 | 35±2.5 | 44±3 | 6±2 | 3.5±0.8 | 4.5±1 | 2±0.8 |

| DRB20(T)-40 | 87±2.2 | 21±2.5 | 12±0.6 | 39±3 | 35±2.5 | 57±3 | 3.5±0.8 | 4.5±1 | 2±0.8 | |

| DRB20(T)-50 | 91±2.4 | 29±3 | 20±1.1 | 47±3 | 43±2.5 | 60±3 | 7±2 | 4.5±1 | 6±1 | 2.5±0.8 |

| DRB20(T)-75 | 140±3.2 | 29±3 | 20±1.1 | 47±3 | 43±2.5 | 110±3 | 7±2 | 4.5±1 | 6±1 | 2.5±0.8 |

| DRB20(T)-100 | 170±3.5 | 29±3 | 20±1.1 | 47±3 | 43±2.5 | 140±3 | 7±2 | 4.5±1 | 6±1 | 2.5±0.8 |

| DRB20(T)-150 | 215±4 | 29±3 | 20±1.1 | 47±3 | 43±2.5 | 185±3 | 7±2 | 4.5±1 | 6±1 | 4±0.8 |

| DRB20(T)-200 | 215±4 | 38±3 | 38±3 | 61±3 | 58±2 | 160±3 | 7±2 | 8±1 | 9±1 | 4±0.8 |

| DRB20(T)-250 | 266±4 | 30±2 | 30±2 | 50±3 | 50±2 | 210±4 | 7±2 | 8±1 | 9±1 | 4±0.8 |

| DRB20(T)-300 | 266±4 | 36±2 | 36±2 | 58±3 | 58±2 | 210±4 | 8±2 | 8±1 | 9±1 | 4±0.8 |

| DRB20(T)-400 | 250±4 | 54±2 | 54±2 | 76±3 | 77±3 | 180±4 | 10±2 | 8±1 | 16±1 | 8±1 |

| DRB20(T)-500 | 300±4 | 54±2 | 30±2 | 76±3 | 77±3 | 230±4 | 10±2 | 8±1 | 16±1 | 8±1 |

| T* : Adjustable Wirewound Resistors。 | ||||||||||

| Power Wirewound Vitreous Enameled Resistors (DRB20) Specification | |||||

| Type | Rating Power (W) | Resistance (Ω) | Weight (g) | ||

| DRB20 | DRB20-T | Fixed | Adjustable | ||

| DRB20 (DRB20T) |

8 | 5.1-3.3K | 23 | ||

| 10 | 5.1-10K | 5.1-200 | 17 | 34 | |

| 16 | 5.1-15K | 5.1-220 | 36 | 42 | |

| 20 | 5.1-20K | 5.1-430 | 44 | 52 | |

| 25 | 10-24 | 10-510 | 57 | 68 | |

| 30 | 10-30K | 10-1K | 80 | 90 | |

| 40 | 20-51K | 20-1.2K | 98 | 110 | |

| 50 | 24-56K | 20-1.5K | 132 | 150 | |

| 75 | 20-51K | 24-2K | 253 | 270 | |

| 100 | 24-62K | 20-4.3K | 286 | 200 | |

| 150 | 20-75K | 20-4.3K | 385 | 300 | |

| 200 | 4.7-68K | 5.1-4.3K | 475 | 400 | |

| 250 | 4.7-68K | 5.1-4.3K | 510 | 530 | |

| 300 | 1.7-68K | 5.1-4.3K | 630 | 650 | |

| 400 | 4.7-75K | 6.2-5.1K | 1000 | 1050 | |

| 500 | 4.7-75K | 6.2-5.1K | 1340 | 1400 | |

| Power Wirewound Enameled Resistor (DRB20) Performance | ||

| Test Item | Characteristics | Test Methods |

| Solderability | Even sticky tin | HiSnPb39, 75W Soldering iron method, tinning |

| Insulation resistance | >20MΩ/cm2 | 500V DC test voltage |

| Insulation voltage | No breakdown, arcing | 2000V DC or 50Hz AC peak with the same |

| Body strength | ΔR ≤ ± (1%R + 0.05Ω) | ≤40W Loading 30N, ≥50W Loading 100N |

| Vibration | ΔR ≤ ± (1%R + 0.05Ω) | Frequency 10-500Hz, Acceleration 98m/s2, 1h |

| Collision test | ΔR ≤ ± (1%R + 0.05Ω) | Frequency 40-80 次/min, Acceleration 245m/s2, 2000 times |

| Temperature Rise | <325°C | Apply rated power Load |

| Rapid temperature changes | ΔR ≤ ± (2%R + 0.1Ω) | θ A=-55°C θ B=+200°C, 5 Cycles |

| Constant Damp Heat | ΔR ≤ ± (2%R + 0.1Ω) | Temperature 40±2°C, Temperature 93±2%RH, 96h |

| Over loading | ΔR ≤ ± (2%R + 0.1Ω) | Apply 10 times the rated power load 5s |

| Room temperature durability | ΔR ≤ ± (5%R + 0.1Ω) | Apply rated power load 1000h |

- Resistance Range means you can choose one maximum resistance value (Max. Pickable Resistance / End resistance value)

at one of DRB20-T, FVR, DQS, DSRA, DSRB, BSR, BSQ, VR (Variable Resistor) type. - After End Resistance Value confirmed, the minimum resistance (start resistance value) will be determined

by depending on resistance of wire and wirewound type.

Power Rating of Variable Resistor:

The part Nunber formation of DRB20-T:

Product type

- Rated Wattage

- Max. Pickable Resistance (Ω)

- Resistance Tolerance

Product type means one of FVR, DQS, DSRA, DSRB, BSR, BSQ, DRB20-T.

Rated Wattage means power rating at End Resistance Value.

Resistance Value (Ω) means maximum resistance value (End Resistance Value).

Resistance Tolerance means precision range of End Resistance Value.

2. Resistance and Power Rating should be decreased while you are adjusting the screw.

Notes:

- Adjustability is 10% to 90% of full resistance value.

- Wattage is proportional to this adjusted resistance value.

Power Rating:

- Based on 25°C free air rating. The stated wattage rating applies only when the entire resistance is in the circuit.

- Setting the lug at an intermediate point reduces the wattage rating by approximately the same proportion.

- Example: If the lug is set at half resistance, the wattage is reduced by approximately one-half.

If you need current constant type or special specifications, please feel free to cntact us.

| Power Wirewound Vitreous Glaze Resistors - (DRB20) Order Codes | ||||||||||||||||||||||||||||||||||||||||||||||||

| DRB20 | T | - | 8W | 100R | J | |||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||

|

|

|

|

|

|

|||||||||||||||||||||||||||||||||||||||||||