Pagination: 2/2

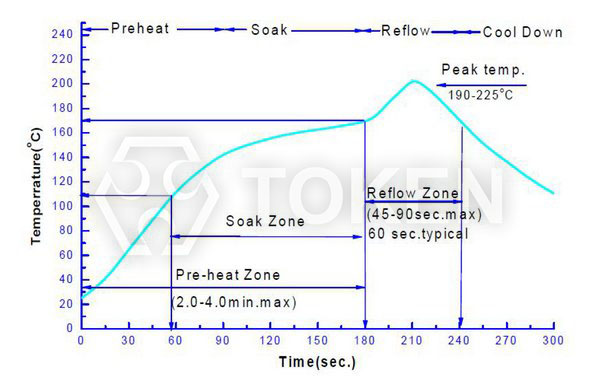

| Recommended Reflow Chart (PT-3528) | ||

|

||

| Characteristic of Temperature Curve | Reference Settings | |

| Average Heating Speed (Tsmax to Tp) | Max. 3°C / Sec | |

| Preheating: Minimum Temperature | (Tsmin) | |

| Preheating: Maximum Temperature (Tsmax) | 150°C | |

| Preheating: Time (tsmin to tsmax) | 60 ~ 120 Sec | |

| Reflow Temperature: Temperature (TL) | 183°C | |

| Period of Reflow: Time (TL) | 60 ~ 150 Sec | |

| Peaking Temperature (TP) | 225°C | |

| Within the Actual Peak Temperature (tp) 5°C | 10 ~ 30 Sec | |

| Cooling speed | Max. 6°C / Sec | |

| 25°C Time required to rise to peak temperature | Max. 6 minutes | |

Storage :

- Without opening the original wrapper, the recommended storage environment is: 5°C ~ 30°C, Humidity less 85%.

- After opening the original wrapper, the recommended storage environment is: 5°C ~ 30°C, Humidity less 60%.

- This product is humidity sensitive device. In order to avoid moisture absorption after unpackage, it is recommended that the opened packaging be stored in an airtight container with desiccant.

- After opening the package, the original should be used within 12 hours.

- If the desiccant fails or the device is exposed to air for more than 12 hours. Should be used for dehumidification treatment at 60°C / 24H.

Baking and dehumidification :

- Use instructions before soldering this product. After opening the original wrapper, product exposure and humid environment. Product may be damaged during soldering.

- Description of the storage: Products with exposure time exceeding the specified time must be baked according to the baking conditions listed below. The following downgrade table determines the maximum amount of time that this product can be exposed to the humidity and temperature conditions listed. (Unit: Day)

- Baking conditions: No need to bake all the products. Baking is required only if the following criteria are met:

- A: Products that have been removed from the original package;

- B: Exposure to humid environments over time which list in Relative Humidity Table.;

- C: Products that have not been soldered. Reflow soldering of parts within one hours after baking, or immediately store the part in a container of relative humidity less than 20%. The product should be baked in its original reel under 60°C for 24 hours. The exposure time of the products after this baking process is again determined by the moisture sensitivity table above.

| Temperature | Maximum Relative Humidity (%) | ||||||

| 30% | 40% | 50% | 60% | 70% | 80% | 90% | |

| 30°C | 9 | 5 | 4 | 3 | 1 | 1 | 1 |

| 25°C | 12 | 7 | 5 | 4 | 2 | 1 | 1 |

| 20°C | 17 | 9 | 7 | 6 | 2 | 2 | 1 |

|

|

||||||||||||||||||||

Service life :

- It can be used for up to 100,000 hours at rated current and rated voltage.

Use and description of Humidity Monitor card :

- The card with "Humiditor" in the bag is the humidity monitor card.

- If there is no humidity in the bag, then the color in the black circle of the monitor card is blue as shown in Figure (1).

- If humidity card "20%" corresponds to the black circle showing the color is pink, then bake and dehumidification the product as shown in Figure (2).

- Humidity card indicates packaging bag humidity conditions.

|

|

||||||||||||||||||||

| Order Codes (PT-3528) | ||||||||||||||||||||||||||||||

| PT | - | IC | - | BC | - | 3528 | - | 550 | ||||||||||||||||||||||

|  |  |  |  | ||||||||||||||||||||||||||

|

|

|

|

|

||||||||||||||||||||||||||